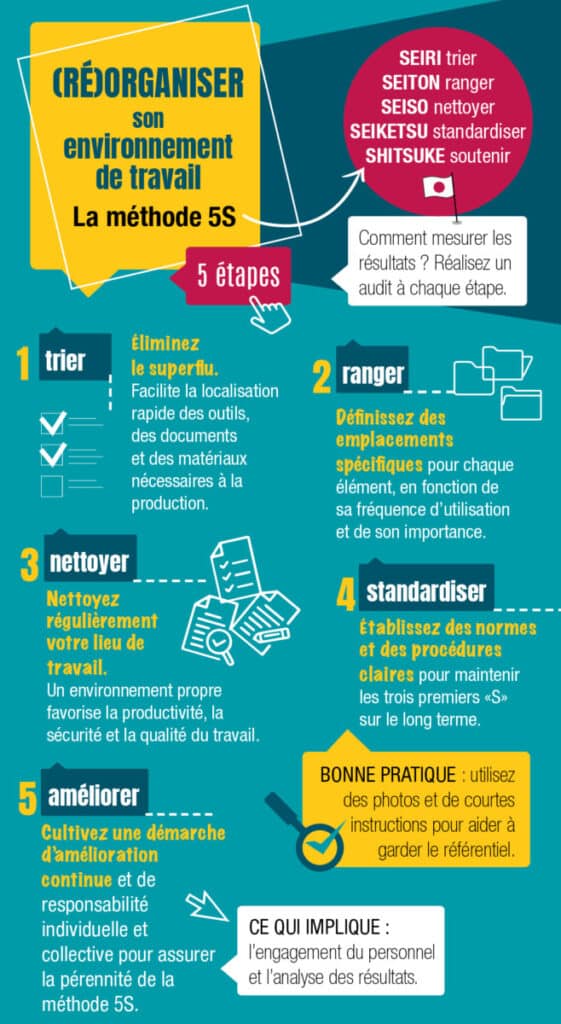

Would you like to (re)organise your office or production workshop? The 5S method is an effective tool for optimising and maintaining your working environment: orderly, productive and safe. So what does this continuous improvement approach involve? What are the benefits? How do you design your pilot project?

Some good practices for implementing the 5S method :

A continuous improvement approach

Step 1: Sort and dispose of unnecessary items in the workplace

Step 2: Store for easy, accessible use

Step 3: Clean the workplace regularly

Stage 4: standardising and maintaining 5S over the long term

A continuous improvement approach

The 5S method is an approach to quality management and workplace organisation that originated in Japan.

The 5S take their name from five Japanese words beginning with "S".

Seiri (Sort), Seiton (Tidy), Seiso (Clean), Seiketsu (Standardise) and Shitsuke (Support).

What are the benefits? This method aims to improve employee efficiency, safety and well-being by eliminating waste, reducing clutter and creating a structured working environment.

Step 1: Sort and dispose of unnecessary items in the workplace

Objective: to sort and select essential items in the workplace. The aim is to distinguish between what is necessary and what is not, eliminating everything that is superfluous.

This step frees up space, reduces clutter and makes it easier to quickly locate the tools, documents and materials needed for production.

How do you measure the results of the 5S method? A stage audit is carried out before moving on to the next stage.

Step 2: Store for easy, accessible use

Objective: to organise and tidy up in a systematic and ergonomic way. This means defining specific locations for each item, according to how often it is used and its importance. A good layout promotes efficiency and reduces the risk of errors and accidents.

Examples

- Sort tools and medicines by category.

- Remove cupboard doors or use Plexiglas. Everything needs to be visible and open.

- Organise the folders by colour.

- To demarcate the area in a warehouse, we mark the location of pallets and pallet trucks with tape.

Step 3: Clean the workplace regularly

Objective: to clean the workplace regularly. This includes keeping equipment, machines, surfaces and workspaces clean.

A clean environment promotes productivity, safety and quality of work by reducing the risk of contamination, malfunctions and accidents.

Stage 4: standardising and maintaining 5S over the long term

The aim is to establish clear standards and procedures for maintaining the first three 'S's over the long term.

Best practice: use photos and short instructions to help keep the reference guide, use short, precise sentences. Photos should show areas that have been sorted and cleaned.

Each sheet corresponds to a zone and the frequency of use must be indicated.

The activity table where these cleaning standards are displayed also needs to be updated.

Step 5: Improve

Objective: to cultivate an approach based on continuous improvement and individual and collective responsibility in order to ensure the long-term future of the 5S method.

Three levers are available to ensure the maintenance and sustainability of the method through the effective interaction of :

People

The success of the 5S method depends on staff commitment. If employees are not motivated to participate in and maintain 5S, it can be difficult to maintain the gains in efficiency and organisation that have been achieved.

Make sure that everyone in the company is aware of the benefits of 5S.

Highlight the successes of your employees and how this affects them positively on a daily basis.

Train everyone in the principles of 5S. Make 5S part of the induction process for new employees.

Process

Implementing 5S can involve initial costs for new storage facilities, cleaning tools and labelling supplies. However, the benefits of a well-implemented 5S method can outweigh these costs.

We need to ensure that all areas are covered by the 5S programme, apply the standards by means of policies and procedures, and integrate 5S worksites with health and safety.

And lastly, integrate 5S communication into department meetings.

Systems

Use 5S posters and signs, check the effectiveness of the programme and monitor the results with appropriate measurements and analyses.

Communicate audit results and progress to all employees.

Reward and recognise employees' efforts.