Flexible, lightweight, easy to program and above all less expensive than traditional robots, cobots are gaining popularity, particularly in SMEs. These robots assist humans in repetitive or dangerous tasks: transporting loads, sorting, packaging, assembly, measurements and analyses... Meet these versatile and tireless workers.

Robots do not know the crisis. France will never have had so many robots in its factories. The year 2022 recorded a record, with a growth of 13 % of industrial robots, according to the International Federation of Robotics (IFR).

One type of robot stands out for its dynamics: cobots, these robots which work safely with humans. Whether they are articulated arms or mobile robots, cobots constitute a small revolution in industrial robotics.

Because, unlike classic industrial robots which work far from humans, in a protective metal cage or suspended above the production line, cobots operate in the same work space as humans. Supported by cobots, humans find themselves relieved of repetitive, boring and risky tasks, which improves their efficiency and well-being while reducing their absenteeism.

Cobots also shine with their versatility. They are found both on assembly production lines and in small SME workshops. We also come across them more and more in warehouses doing pick and place (moving the goods from one place to another), palletizing or packaging. Enough to respond to the chronic shortage of labor for these repetitive tasks of order preparation and packing.

What is a cobot?

The cobot takes its name from the contraction of “ collaborative robot » or collaborative robot. It is a robot that works in collaboration with a human operator. Robot and human therefore share the same space.

The whole thing first cobot was designed in 1996 at the American University of Northwestern by professors James Colgate and Michael Peshkin. Their goal was to reduce the workload of employees at General Motors' automobile plants by automating grueling tasks.

This first cobot was nothing extraordinary: a simple wheel and a motor guided by a program.

It was in the 2000s that the first cobots were marketed. The Kuka Robotics brand, which also produces classic industrial robots, marketed its first cobot, the LBR 3 in 2004.

One of the largest cobot manufacturers, the Danish Universal Robotics, launched its first cobot, the UR5, in 2008.

The different types of cobots

What does a cobot look like? It exists two main categories: articulated arms and mobile robots.

Robotic arms

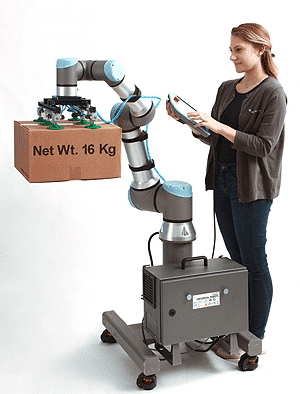

Robotic arms are anthropomorphic robots in the form of arms capable of manipulating objects, assembling, screwing, welding, sanding, gluing, painting… or packaging. Thanks to their precise movements, they work with precision.

The UR16 robotic arm from Universal Robotics is capable of lifting 16 kilos.

How to choose it? The main characteristics to take into account are the maximum payload (from 2 to 30 kg depending on the model), the working radius or the maximum reach (from 500 to 1500 mm approx.) and the number of axes which will determine the degree of freedom and flexibility of the robot, the possibility of reaching more complex positions making it suitable for a wider range of applications.

Mobile robots (AGV and AMR)

On their side, mobile robots are the big trend of the moment. We distinguish the automatic guided vehicles (AGV) and autonomous mobile robots (AMR). The main difference between AMR and AGV is the navigation system. While the AGVs move along a predefined path using laser or wire-guided (buried wire) guidance systems, the AMRs adapt their trajectory in real time in connection with the warehouse management software. company that controls their movements.

Their role is mainly to move these goods. They can transport hundreds of kilos on each trip in complete safety for humans.

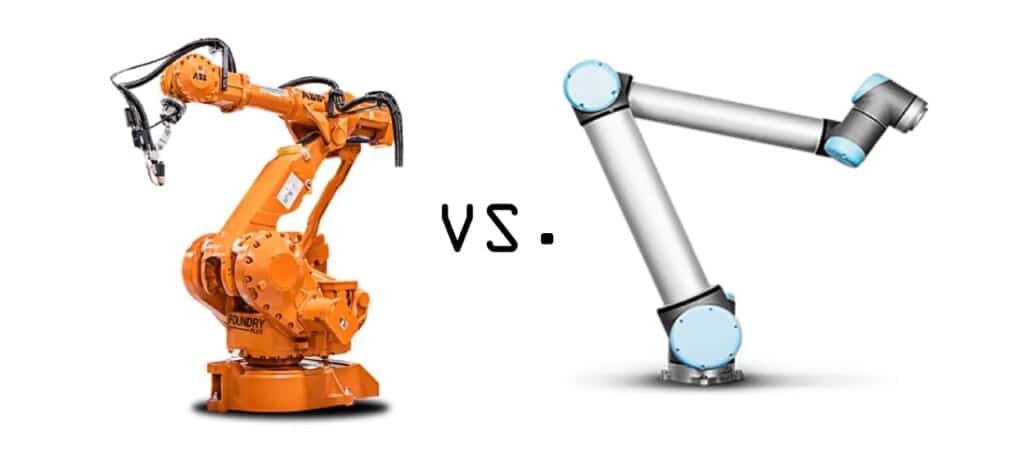

The differences between robots and cobots

Security and the “human friendly” side

Operating close to humans requires that the cobot incorporate a whole range of safety systems in order to perceive its environment, know where the humans are at all times, prevent any risk of collision and increase safety. Equipped with force and torque sensors (to adapt their power and speed), radars, lasers or cameras, cobots avoid any physical contact with a human. And, if unfortunately this happens, they can automatically shut down.

If it is alone, the cobot advances on its task at full speed, but it will slow down as soon as a person approaches and will stop automatically if it is touched or if it detects an obstacle. It will resume its activity as soon as the person leaves.

Other elements contribute to safety: a deliberately reduced execution speed, a low mass (a few kilos) compared to that of industrial robots, rounded and non-protruding edges, low operating noise, soft colors and soothing (white, blue), etc.

Safety standards and rules govern the use of collaborative robots, in particular the ISO 10218 standard which defines the safety principles (safety stopping, manual guidance, speed control, etc.) and the ISO 15066:2016 standard. which defines technical specifications (force and pressure thresholds, etc.) that manufacturers must respect.

An affordable price

Smaller and simpler to install, cobots are also much cheaper than traditional industrial robots. Count between approximately 10,000 and 50,000 euros, or up to ten times less than their industrial equivalent. As a result, their return on investment is very rapid, around 195 days on average.

Ease of programming

Unlike a traditional industrial robot, a cobot is operational in record time. Very simple to program, you just need to use an application to describe the tasks to be accomplished. No code is needed. Another possibility: programming by learning, based increasingly on artificial intelligence, makes it possible to teach the robot the gestures to do by manipulating it using the application.

Generally speaking, cobots easily adapt to new parameters, new working environments, new parts to be treated. They are more versatile than traditional industrial robots and adapt more easily to changes in position or production.

Performances

A cobot will be less efficient than an industrial robot in order to minimize the risk of accidents with humans. With reduced working speed and lighter workloads, between 3 and 30 kg depending on the model, their production volumes are lower. They are more suitable for manufacturing small series or precision work.

A new human-machine relationship

While industrial robots aim to improve the speed and quantities of production, cobots generate direct productivity gains such as the performance of human operators who concentrate on tasks with higher added value, but also indirect gains such as improving the quality of processes as well as the safety and quality of life of workers.

Designed to lift and manipulate heavy loads, industrial robots work wonders on assembly tasks. For their part, cobots are particularly suitable for low load ports, in finishing applications, assembly of small parts (electronics), bonding-welding, movement of parts (pick and place), quality control (chips, touch screen, etc.), handling, packaging and palletizing.

We will therefore naturally find them in the consumer goods industry, electronics and at work in warehouses for packaging.

Before implementing a cobotics solution, you will need to think about its integration, as with any new technology. This requires analyzing demand and needs (flow, cadences, etc.), analyzing the work both from the point of view of the position and ergonomics, supporting the teams to familiarize them with the robot so that the man-machine relationship is goes as well as possible.