Often misunderstood or even misunderstood, lean is nevertheless a method with many advantages for the organisation of companies. Between the need for agility and the need for optimisation, lean appears to be the solution that best reconciles these two improvement objectives. Hugo Maisonnial talks to ORSYS about lean as a lever for continuous improvement.

Being lean means being slender

Initiated by Toyota in the 1950s, lean aims to identifying and eliminating waste. In other words, it means eliminating or transforming all the activities, all the time we spend doing something, all the resources (material and human) we use, and who have no added value for the customer, the company or the employees.

The term 'lean', too often associated with 'degreasing' activities (due to a haphazard translation: thin/lean), is preferred to 'lean'. "svelte", i.e. doing 'better' with the same resources, while putting people at the heart of the approach.

Thought through over the long term, lean has real advantages for all of a company's activities. It establishes a long-term approach, encourages stable and collective organisation, and combats waste. It also facilitates digitalisation by, for example, naturally encouraging dematerialisation.

Lean is not just for industry

Historically, lean was first widely deployed in various industries (automotive, aeronautics, pharmaceuticals, etc.). Today, all business sectors is likely to use this methodology (public services, service companies, banking sector, etc.).

In all our business lines and in all our activities, we carry out a thorough sequence of tasks to bring the product, service or information to the state desired by the customer: this is known as a "process". Each of these successive stages adds value but can also be wasteful. At this stage, avenues for improvement emerge. Lean is all about optimisation.

To put it plainly, lean doesn't focus on one area of activity, but on one process. It is therefore applicable everywhere, all the time, provided you understand the issues and master the tools.

Lean as a culture of continuous improvement

Lean is above all an identified culture mainly through behaviours, which in turn stem from the use of tools. It is based on four pillars teamwork, communication, efficient use of resources and elimination of waste.

For successful implementation, it is essential to :

- define the policy for rolling out continuous improvement at company level, and communicate a clear vision (e.g. improving quality/reducing lead times) ;

- to align the entire organisation around a common objective, or in other words toinvolve as many people as possible develop a mindset of continuous improvement. In practice, this means question processes and not people.

Supporting change to perpetuate the lean approach

The launch of a lean approach within a company can encounter obstacles, particularly during transformation projects. Quite "classically", these include difficulties encountered in managing change :

- no corporate vision = we are in a state of confusion;

- no know-how = anxiety;

- without motivation = we are in a state of slow change;

- no resources = frustration;

- no action plans = false starts.

Vigilance is therefore essential at all stages of the project, and particularly after the deployment phases. To ensure that the lean approach lasts, it will be necessary to ensure that continuous improvement is fully embedded in the company's culture.

Tools are good. Culture is better.

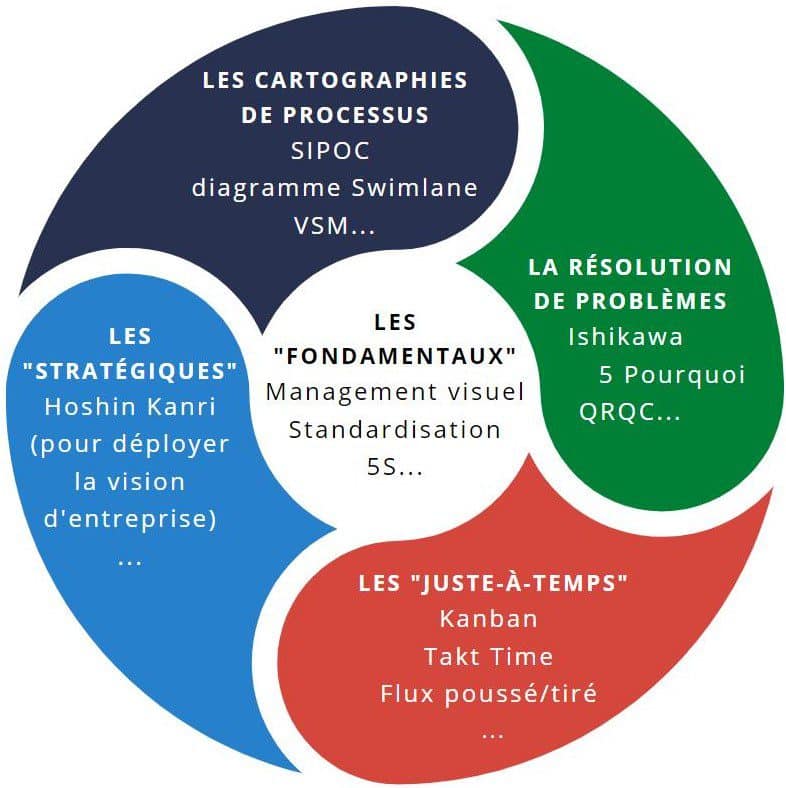

The Lean toolbox is rich and various. In particular, we find tools:

- (5S, Visual Management, standardisation, etc.);

- Process mapping (SIPOC, Swimlane diagram, VSM, etc.);

- aimed at problem solving (Ishikawa, 5 Whys, QRQC, etc.);

- Just-in-time" (Kanban, Takt Time, Push/Pull Flow, etc.);

- such as 'Hoshin Kanri' to deploy the corporate vision.

We often hear that lean is based on "Practicality. That's true, but... Based on our experience (recent graduate or very experienced person) or our culture (American, Korean, French...), we may not all have the same "practical sense".

Beyond the tools, lean is above all a state of mind.That of see problems as opportunities to improve.